电控系统 英语,Introduction to Electric Control Systems

时间:2024-12-21 来源:网络 人气:

Introduction to Electric Control Systems

Electric control systems are integral to the functioning of modern technology, from industrial machinery to consumer electronics. This article delves into the basics of electric control systems, their components, and their applications across various industries.

Components of an Electric Control System

Electric control systems are composed of several key components that work together to achieve a desired outcome. These include:

Control Panel: The central hub where all the components are connected and controlled. It typically includes switches, relays, and indicator lights.

Power Supply: Provides the necessary electrical energy to operate the system. This can be in the form of AC or DC power, depending on the application.

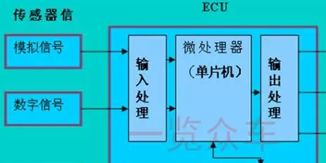

Control Circuits: These circuits process and interpret signals from sensors and other devices, making decisions based on the input data.

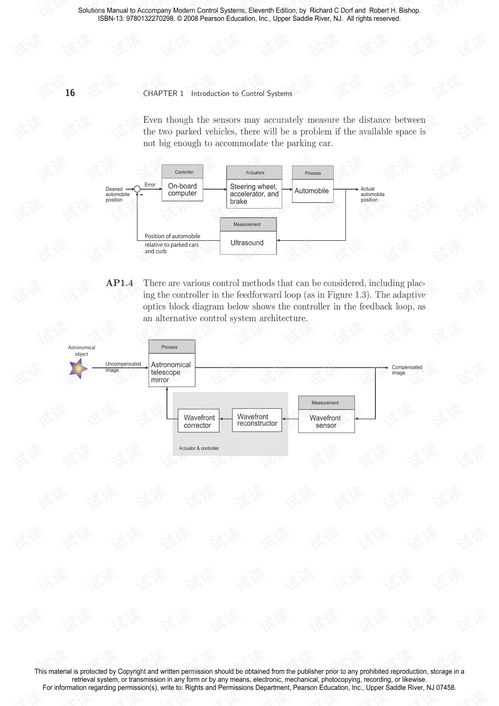

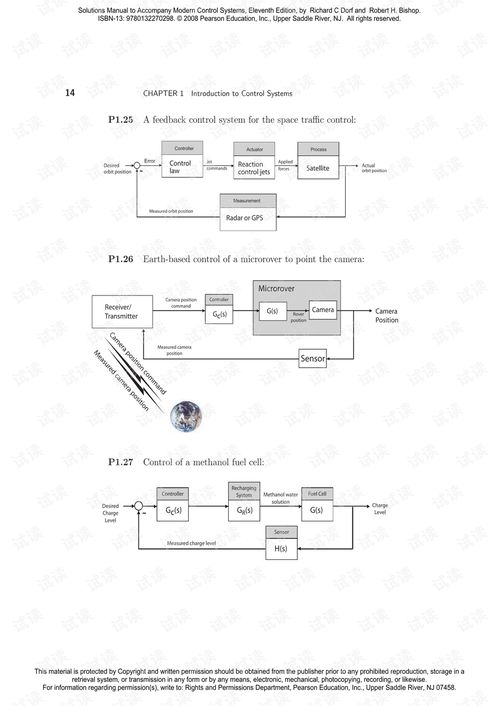

Actuators: Devices that convert control signals into physical actions, such as opening or closing valves, starting or stopping motors, or adjusting the position of a mechanism.

Sensors: Devices that detect and measure physical quantities, such as temperature, pressure, or position, and convert them into electrical signals that can be processed by the control circuits.

Types of Electric Control Systems

Electric control systems can be categorized into different types based on their application and design. Some common types include:

Programmable Logic Controllers (PLCs): Used in industrial automation, PLCs are programmable devices that control the operation of machinery and processes. They are known for their flexibility, reliability, and ease of programming.

DCS (Distributed Control System): A network of interconnected control systems that allows for centralized monitoring and control of industrial processes. DCS systems are commonly used in power plants, oil refineries, and chemical plants.

SCADA (Supervisory Control and Data Acquisition): A system that collects and processes data from remote monitoring stations and sends control signals to automated systems. SCADA systems are widely used in utilities, transportation, and manufacturing industries.

Applications of Electric Control Systems

Electric control systems are used in a wide range of applications across various industries. Some notable examples include:

Automotive Industry: Electric control systems are used in modern vehicles for engine management, anti-lock braking systems (ABS), and advanced driver-assistance systems (ADAS).

Manufacturing Industry: Electric control systems are used to automate production lines, improve efficiency, and ensure product quality in manufacturing processes.

Power Generation and Distribution: Electric control systems are essential for managing power generation, transmission, and distribution networks, ensuring reliable and efficient power supply.

Healthcare Industry: Electric control systems are used in medical devices, such as MRI machines, ventilators, and patient monitors, to provide accurate and reliable diagnostics and treatment.

Challenges and Future Trends

Despite the numerous benefits of electric control systems, there are challenges that need to be addressed. These include:

Complexity: As systems become more sophisticated, the complexity of design and maintenance increases.

Reliability: Ensuring the reliability of electric control systems in harsh environments is a critical concern.

Security: With the increasing connectivity of systems, ensuring cybersecurity is a growing challenge.

Looking ahead, some future trends in electric control systems include:

Artificial Intelligence (AI): Incorporating AI into control systems can improve decision-making and optimize performance.

Internet of Things (IoT): Connecting control systems to the IoT can enable real-time monitoring and predictive maintenance.

Energy Efficiency: Developing more energy-efficient control systems is crucial for reducing environmental impact.

Conclusion

相关推荐

教程资讯

教程资讯排行